FREE SHIPPING FROM 80 € IN IRELAND

Discount 10%, 13% and 16%

CATEGORIES

- SHARPENERS

- AIRSOFT

- ARCS

- ARMS

- CAMPING AND SURVIVAL

- HUNTING AND OBSERVATION

- COSAS

- PROFESSIONAL KNIVES

- HUNTING KNIVES

- LUXURY KNIVES

- HUNTING KNIVES

- SWORDS

- EXHIBITORS

- KEYCHAINS AND PINS

- MACHETES

- KITCHEN-UTENSILS

- MULTIPURPOSE

-

POCKETKNIVES

- FAN

- SHAVE

- FARMER POCKET KNIVES

- ARTISANS

- CABRITERA POCKET KNIVES

- FIELDS

- CLASSIC SPAIN

- COLLECTION

- SHORT MUSHROOMS

- DAMASCUS

- DWARFS GIANTS

- STYLET

- GRAFTING POCKET KNIVES

- LAGUIOLE

- SAILORS POCKET KNIVES

- CUT TIP POCKET KNIVES

- TRANCHETES

- VENDETTA

- BUSHCRAFT

- HUNTING

- SHEATHES

- MILITARY

- MOUNTAIN

- SPORTS

- TACTICAL

- POCKETKNIVES CLASSIC SPAIN

- OBJECTS PERSONAL

- OTHERS

- SCISSORS

- VARIUOS

BRANDS

- 3 CLAVELES

- ACERO TOLEDANO

- AGEO

- AITOR

- AMONT

- ARCOS

- ATK

- AZERO

- BARBARIC

- BEAVERCRAFT

- BENCHMADE

- BLACK FOX

- BOKER

- BRISA

- BUCK

- BUNMEI

- CELAYA

- CITADEL

- COLD STEEL

- CRKT

- CROSSNAR

- CUDEMAN

- DENIX

- DMT

- DON BENITO

- DOVO HEROLD

- EXPOSITO

- EXTREMA RATIO

- EXTREMEÑA

- FAMACU

- FILARMONICA

- FOX MILITARY

- GAMO

- GERBER

- GK PROFESSIONAL

- GLADIUS

- GLOBAL

- GOLDEN EAGLE

- HATSAN

- HELLE

- HERBERTZ

- ISIDRO ARTESANO

- JJ CUCHILLERIA

- JKR

- JL RUBIO

- JOKER

- JV CDA

- K25

- KABAR

- KAI

- KASUMI

- KERSHAW

- KOLSER

- KYOCERA

- LEATHERMAN

- LES FINES LAMES

- MACTRONIC

- MAGNUM

- MAM

- MARTINEZ ALBAINOX

- MARTINEZ Y GASCON

- MARTO

- MARTTIINI

- MASTODON

- MECHANIX WEAR

- MORAKNIV

- MUELA

- NIETO

- NJORD

- OPINEL

- PALLARES

- PELTONEN

- POMONI

- PUMA

- RADAR 1957

- RUI

- SALAMANDRA

- SILKY

- SMITH WESSON

- SOG

- SPYDERCO

- STANLEY

- SWIZA

- SWORDS FROM TOLEDO

- THIRD

- TOLEDO IMPERIAL

- UST

- VICTORINOX

- WINDLASS

- WITHARMOUR

- WOLL

- WUSTHOF

CATEGORIES

- SHARPENERS

- AIRSOFT

- ARCS

- ARMS

- CAMPING AND SURVIVAL

- HUNTING AND OBSERVATION

- PROFESSIONAL KNIVES

- HUNTING KNIVES

- LUXURY KNIVES

- HUNTING KNIVES

- SWORDS

- EXHIBITORS

- KEYCHAINS AND PINS

- MACHETES

- KITCHEN-UTENSILS

- MULTIPURPOSE

-

POCKETKNIVES

- FAN

- SHAVE

- FARMER POCKET KNIVES

- ARTISANS

- CABRITERA POCKET KNIVES

- FIELDS

- CLASSIC SPAIN

- COLLECTION

- SHORT MUSHROOMS

- DAMASCUS

- DWARFS GIANTS

- STYLET

- GRAFTING POCKET KNIVES

- LAGUIOLE

- SAILORS POCKET KNIVES

- CUT TIP POCKET KNIVES

- TRANCHETES

- VENDETTA

- BUSHCRAFT

- HUNTING

- SHEATHES

- MILITARY

- MOUNTAIN

- SPORTS

- TACTICAL

- POCKETKNIVES CLASSIC SPAIN

- OBJECTS PERSONAL

- SCISSORS

- VARIUOS

BRANDS

- 3 CLAVELES

- ACERO TOLEDANO

- AGEO

- AITOR

- AMONT

- ARCOS

- ATK

- AZERO

- BARBARIC

- BEAVERCRAFT

- BENCHMADE

- BLACK FOX

- BOKER

- BRISA

- BUCK

- BUNMEI

- CELAYA

- CITADEL

- COLD STEEL

- CRKT

- CROSSNAR

- CUDEMAN

- DENIX

- DMT

- DON BENITO

- DOVO HEROLD

- EXPOSITO

- EXTREMA RATIO

- EXTREMEÑA

- FAMACU

- FILARMONICA

- FOX MILITARY

- GAMO

- GERBER

- GK PROFESSIONAL

- GLADIUS

- GLOBAL

- GOLDEN EAGLE

- HATSAN

- HELLE

- HERBERTZ

- ISIDRO ARTESANO

- JJ CUCHILLERIA

- JKR

- JL RUBIO

- JOKER

- JV CDA

- K25

- KABAR

- KAI

- KASUMI

- KERSHAW

- KOLSER

- KYOCERA

- LEATHERMAN

- LES FINES LAMES

- MACTRONIC

- MAGNUM

- MAM

- MARTINEZ ALBAINOX

- MARTINEZ Y GASCON

- MARTO

- MARTTIINI

- MASTODON

- MECHANIX WEAR

- MORAKNIV

- MUELA

- NIETO

- NJORD

- OPINEL

- PALLARES

- PELTONEN

- POMONI

- PUMA

- RADAR 1957

- RUI

- SALAMANDRA

- SILKY

- SMITH WESSON

- SOG

- SPYDERCO

- STANLEY

- SWIZA

- SWORDS FROM TOLEDO

- THIRD

- TOLEDO IMPERIAL

- UST

- VICTORINOX

- WINDLASS

- WITHARMOUR

- WOLL

- WUSTHOF

DESIGN PLUS

Products

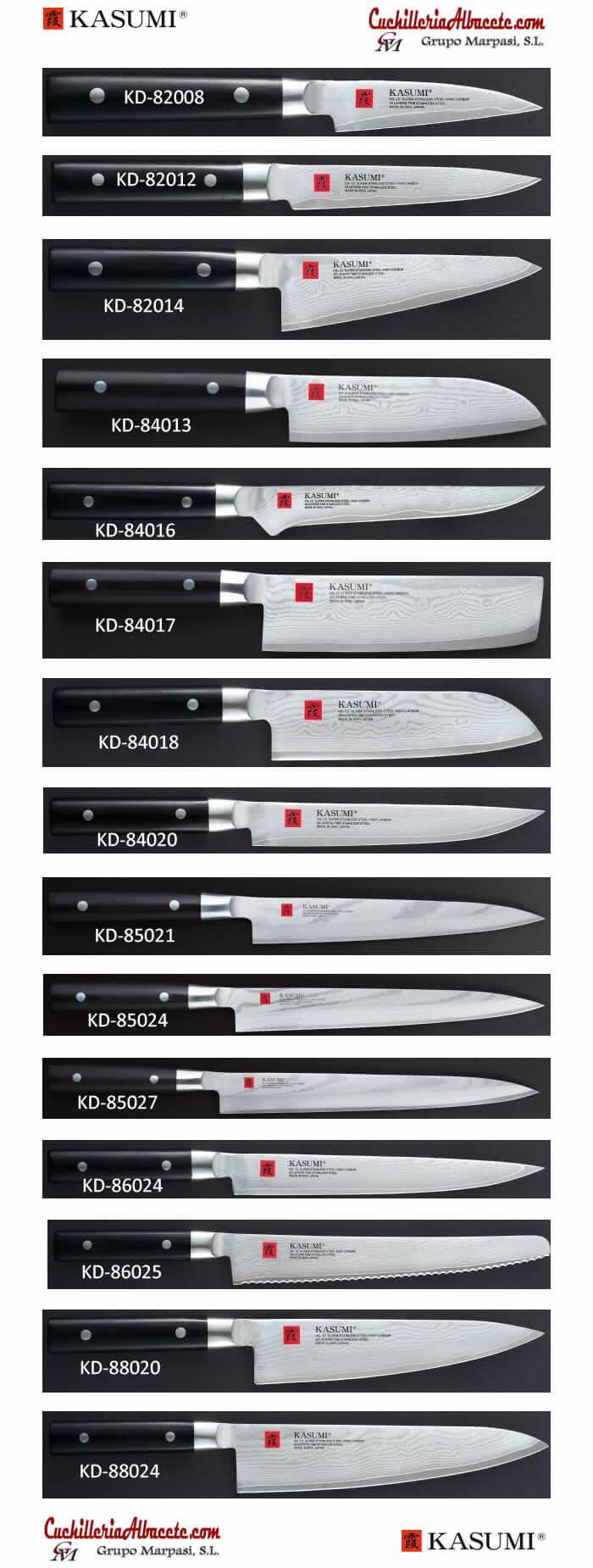

DAMASCENE KASUMI

This range of knives is made of by 33 sheets of stainless steel, with only the center piece which acts as a blade. This copy is made of steel V-GOLD 10 containing a high percentage of carbon, cobalt, manganese and molybdenum vanadium, which apart from giving strength and quality of cut to the leaf, also facilitates its sharpness. Importantly, steel V-Gold 10 is a type of steel created especially for the manufacture of knives and scissors.

The addition of cobalt to steel required to conduct a special hardening process to maximize the qualities of the alloy, which prolongs the process of making damask knife. This technique has SUMIKAMA is all a secret even to its distributors worldwide.

The manufacturing process of the layers surrounding the sheet of V-Gold No. 10 is special: It consists of a succession of one layer of steel with a high proportion of carbon followed by another layer of low-carbon ratio.

Bending are, first, two layers of stainless steel and then forged re-double again. And so on until you get 16 thin slices, which will later be forged with the central sheet of V-Gold 10. This sequence of layers is achieved equally in the process of "Orikaeshi Tanren" of a Japanese katana, ie, stretch, bend, stretch and then return to bend, and so on. This succession, of different layers, resulting in a complex and unique texture. The knife blade is then hardened in the range of Rockwell C59 - 60 degrees.

This range of knives is made of by 33 sheets of stainless steel, with only the center piece which acts as a blade. This copy is made of steel V-GOLD 10 containing a high percentage of carbon, cobalt, manganese and molybdenum vanadium, which apart from giving strength and quality of cut to the leaf, also facilitates its sharpness. Importantly, steel V-Gold 10 is a type of steel created especially for the manufacture of knives and scissors.

The addition of cobalt to steel required to conduct a special hardening process to maximize the qualities of the alloy, which prolongs the process of making damask knife. This technique has SUMIKAMA is all a secret even to its distributors worldwide.

The manufacturing process of the layers surrounding the sheet of V-Gold No. 10 is special: It consists of a succession of one layer of steel with a high proportion of carbon followed by another layer of low-carbon ratio.

Bending are, first, two layers of stainless steel and then forged re-double again. And so on until you get 16 thin slices, which will later be forged with the central sheet of V-Gold 10. This sequence of layers is achieved equally in the process of "Orikaeshi Tanren" of a Japanese katana, ie, stretch, bend, stretch and then return to bend, and so on. This succession, of different layers, resulting in a complex and unique texture. The knife blade is then hardened in the range of Rockwell C59 - 60 degrees.